O retrofit na indústria de manufatura refere-se ao processo de modernização e atualização de máquinas e equipamentos que estão obsoletos ou inadequados para os processos produtivos atuais. Isso pode envolver a substituição ou atualização de componentes específicos, mas o objetivo é melhorar a eficiência, produtividade e segurança do equipamento sem a necessidade de substituí-lo completamente.

Dessa forma, o retrofit pode incluir a troca de partes mecânicas desgastadas, a atualização de sistemas eletrônicos com novas tecnologias – como sensores e automação – e melhorias na eficiência energética.

Existem vários tipos de retrofit na indústria de manufatura, cada um focado em diferentes aspectos dos equipamentos e sistemas. Aqui estão alguns dos principais tipos:

- Retrofit Mecânico: Envolve a substituição ou atualização de componentes mecânicos desgastados ou obsoletos, como motores, engrenagens e rolamentos.

- Retrofit Eletrônico: Atualização de sistemas eletrônicos, incluindo a instalação de novos sensores, controladores, sistemas de automação e software de monitoramento em tempo real.

- Retrofit Hidráulico: Modernização de sistemas hidráulicos, substituindo componentes como bombas, válvulas e cilindros para melhorar a eficiência e a confiabilidade.

- Retrofit de Eficiência Energética: Implementação de tecnologias e componentes que reduzem o consumo de energia, como motores de alta eficiência e sistemas de controle de energia.

- Retrofit de Segurança: Atualização de sistemas de segurança para atender às normas e regulamentos atuais, incluindo a instalação de dispositivos de proteção, sensores de segurança e sistemas de parada de emergência.

Cenários que levam a indústria a buscar alternativas de modernização

Buscando a modernização, e, levando em consideração os desafios significativos como a obsolescência tecnológica, o consumo excessivo de energia eleva os custos operacionais, impactando o meio ambiente e as necessidades atuais das produções. Nesse sentido, a substituição dos componentes por versões mais eficientes e a implementação de sistemas de controle avançados são alternativas viáveis para mitigar esses problemas.

Outro fator crítico é o alto custo de manutenção. Com o tempo, a manutenção de equipamentos antigos se torna cada vez mais cara e complexa, com peças de reposição difíceis de encontrar e uma frequência crescente de falhas.

A conformidade com normas e regulamentações também é um aspecto importante, já que as normas de segurança, meio ambiente e qualidade estão em constante evolução. Equipamentos antigos podem não estar em conformidade com as exigências atuais, expondo a empresa a riscos legais e operacionais. A atualização dos sistemas garante a conformidade com as normas vigentes, assegurando também a segurança dos trabalhadores.

Por fim, a baixa produtividade resultante da falta de confiabilidade dos equipamentos antigos pode levar a paradas frequentes e baixa velocidade de produção. Isso afeta diretamente a capacidade das indústrias de atender a demanda do mercado e manter a competitividade. Melhorias na confiabilidade e na performance dos sistemas aumentam a produtividade.

Desafios do Retrofit em Equipamentos Industriais

Embora o retrofit ofereça várias vantagens, ele também apresenta alguns aspectos negativos que devem ser considerados:

- Custo Inicial Elevado: Dependendo da extensão das atualizações necessárias, o custo inicial do retrofit pode ser alto. Isso inclui a compra de novos componentes, mão de obra especializada e possíveis interrupções na produção.

- Tempo de Parada: A implementação do retrofit pode exigir que as máquinas e equipamentos fiquem fora de operação por um período, o que pode impactar a produtividade e os prazos de entrega.

- Complexidade Técnica: O retrofit pode ser tecnicamente complexo, especialmente quando envolve a integração de novas tecnologias com sistemas antigos. Isso pode exigir um planejamento detalhado e a contratação de especialistas para garantir a compatibilidade e o desempenho adequado.

- Riscos de Incompatibilidade: Há o risco de incompatibilidade entre os novos componentes e os sistemas existentes, o que pode resultar em falhas ou desempenho subótimo.

- Manutenção Preditiva: Integrar sistemas de manutenção preditiva em máquinas legadas pode ser tecnicamente desafiador. A precisão e a confiabilidade dos dados são cruciais para o sucesso desse processo e, embora o retrofit melhore alguns aspectos dos equipamentos, muitas vezes não garante a integração completa e eficiente necessária para a manutenção preditiva, devido às limitações dos sistemas antigos.

- Retorno sobre o Investimento (ROI) Incerto: Em alguns casos, o retorno sobre o investimento pode ser incerto, especialmente se os benefícios esperados em termos de eficiência e produtividade não forem alcançados.

Manufatura Inteligente: A Vantagem da Ciência de Dados e IoT sobre o Retrofit

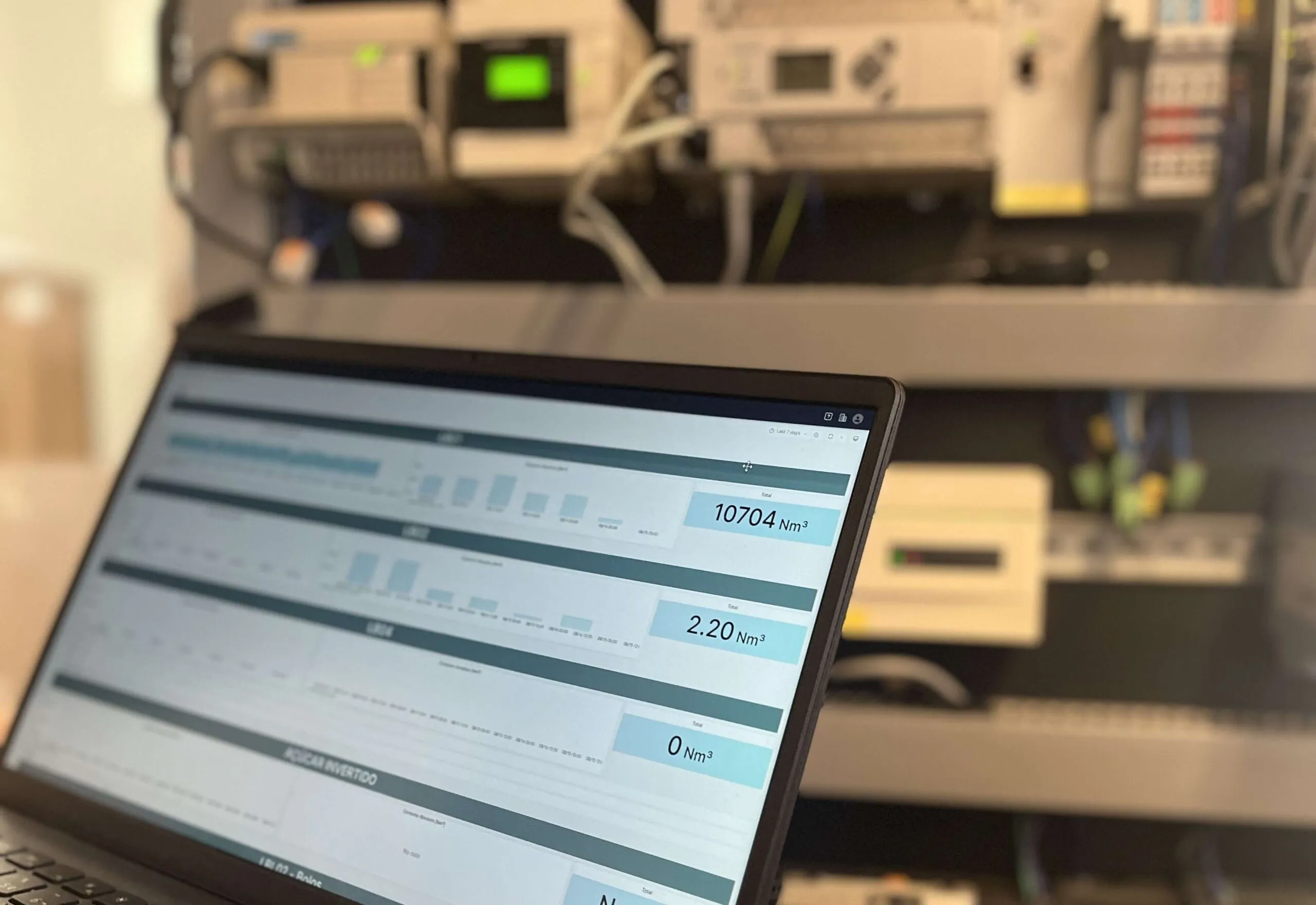

A adoção de tecnologias IoT (Internet das Coisas) e Big Data em indústrias de manufatura são uma alternativa eficaz ao retrofit, proporcionando melhorias significativas em eficiência, redução de custos e qualidade dos produtos. A coleta contínua de dados em tempo real permite análises de identificação de padrões e anomalias, evitando falhas, paradas não planejadas e otimizando processos.

A Ciência de Dados desempenha um papel importante nesse contexto, pois transforma grandes volumes de dados em insights acionáveis. Por exemplo, a manutenção preditiva, baseada em análise de dados, pode prever falhas em equipamentos antes que ocorram, reduzindo o tempo de inatividade e os custos de reparo. Além disso, a otimização de processos produtivos através de algoritmos de machine learning pode aumentar a eficiência operacional e a qualidade dos produtos, ajustando parâmetros de produção em tempo real.

O estudo “O Sistema Tecnológico Digital: inteligência artificial, computação em nuvem e Big Data” (2020) destaca que a integração de novas tecnologias na manufatura não apenas melhora a eficiência, mas também contribui para a sustentabilidade, ao reduzir o desperdício de materiais e energia.

A escolha entre retrofit e Ciência de Dados com IoT depende das necessidades específicas da indústria. O retrofit apresenta algumas limitações técnicas significativas. Nem todos os equipamentos podem ser adaptados com novas tecnologias, o que pode restringir a modernização de certas máquinas. Além disso, o retrofit pode não garantir a mesma durabilidade que uma substituição completa, resultando em uma vida útil reduzida dos equipamentos atualizados.

Por outro lado, a Ciência de Dados combinada com IoT oferece diversos benefícios. Sua aplicação pode transformar significativamente a segurança e a robustez do ambiente fabril. Quando tecnologias como essas são implementadas em conformidade com padrões rigorosos de segurança, como o SOC2, que garante a proteção e integridade dos dados, a confiança na segurança das operações aumenta.

Saiba mais sobre a ST-One.