A análise de balanço de massa é uma ferramenta essencial na engenharia de processos, utilizada para quantificar perdas de insumo ao longo de sistemas produtivos. Sua aplicação permite rastrear o comportamento das matérias-primas, produtos e resíduos em cada etapa, promovendo maior controle e eficiência operacional. Para isso, é necessário considerar variáveis fundamentais, como fluxos de entrada e saída, composição das correntes, taxas de vazão, acúmulo e perdas. A confiabilidade da análise depende diretamente da qualidade e estabilidade dos dados coletados, além da existência de um histórico para comparação e identificação de desvios.

Essa metodologia é amplamente empregada em diferentes fases do ciclo industrial: desde o desenvolvimento e otimização de processos, até o controle de qualidade, monitoramento contínuo e gestão de resíduos. A equação geral de balanço de massa é adaptável a diferentes contextos e setores, podendo ser aplicada de forma estacionária ou não estacionária, diferencial ou integral, global ou por componente, com ou sem reação química. Por exemplo, em processos contínuos como a destilação, adota-se o balanço estacionário, enquanto a fermentação em batelada demanda um modelo não estacionário. Em sistemas com reações rápidas, o modelo diferencial é mais adequado, e em operações com limites temporais bem definidos, como bateladas, utiliza-se o balanço integral. Já o balanço por componente ou global permite uma visão segmentada ou total do processo, sendo indispensável para análises de separação ou de desempenho de plantas inteiras.

Aplicado corretamente, o balanço de massa oferece suporte estratégico para reduzir perdas, melhorar a produtividade, assegurar a conformidade ambiental e aprimorar a tomada de decisões industriais com base em dados técnicos precisos.

Sistematização em Processos Industriais Complexos

As análises de balanço de massa são ferramentas fundamentais na engenharia industrial, com ampla aplicabilidade em diferentes contextos produtivos. No entanto, sua execução pode se tornar complexa em processos com múltiplos equipamentos interligados, especialmente quando envolvem sistemas multifásicos, heterogêneos ou com reações químicas. Nessas situações, a organização e a sistematização das informações tornam-se indispensáveis para garantir uma abordagem clara e objetiva.

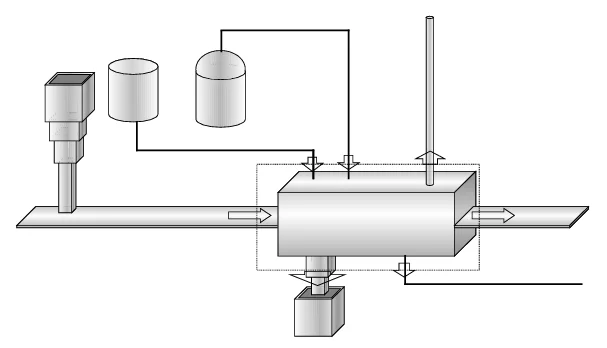

Segundo Mazzuco (2013), o equacionamento eficaz de análises de trânsito de massa deve seguir etapas bem definidas: elaborar um diagrama detalhado do processo, delimitar a área de estudo, quantificar todas as correntes e seus constituintes, reunir equações que relacionem as variáveis do sistema, incorporar informações complementares e definir uma base de cálculo consistente. Esses passos estruturam a análise e possibilitam maior precisão nos resultados.

Apesar da importância, muitas indústrias enfrentam obstáculos que limitam a aplicação do balanço de massa. Entre os principais desafios estão a ausência de dados confiáveis, a alta variabilidade operacional e a dificuldade de integrar as informações necessárias. A falta de uma coleta de dados robusta e estruturada compromete diretamente a consistência da análise, podendo resultar em diagnósticos incompletos ou imprecisos.

Exemplos práticos reforçam a utilidade da ferramenta. Na produção de cerveja, na indústria de bebidas, as entradas incluem água, malte, lúpulo e levedura, passando por etapas como moagem, brassagem, fermentação e filtração. As saídas envolvem cerveja, bagaço de malte e resíduos de fermentação. O balanço de massa permite calcular precisamente os insumos necessários para cada volume produzido e os resíduos gerados. Já na indústria de papel e celulose, a produção de papel parte de madeira, água e produtos químicos, como a soda cáustica. Com o balanço de massa, é possível quantificar os materiais exigidos e os resíduos, como o licor negro, contribuindo para maior controle e eficiência do processo.

Aplicação da Análise de Balanço de Massa no processo de Plástico Polietileno

Um exemplo de um produto final complexo e comum na indústria química é o plástico de polietileno. A produção de polietileno envolve várias etapas e reações químicas complexas:

- Produção de Eteno: O processo começa com a produção de eteno (etileno) a partir de hidrocarbonetos como o etano, através de um processo chamado craqueamento a vapor. O etano é aquecido a altas temperaturas (800-900°C) na presença de vapor, resultando na formação de eteno e outros subprodutos.

- Polimerização: O eteno é então polimerizado para formar polietileno. Existem diferentes métodos de polimerização, como:

- Polimerização em Fase Gasosa: O eteno é polimerizado em um reator de fase gasosa usando catalisadores específicos.

- Polimerização em Solução: O eteno é dissolvido em um solvente e polimerizado em presença de catalisadores.

- Polimerização em Suspensão: O eteno é polimerizado em um meio líquido, onde o polietileno formado é suspenso.

- Controle de Reações: A polimerização é controlada para obter diferentes tipos de polietileno, como polietileno de alta densidade (HDPE) e polietileno de baixa densidade (LDPE), cada um com propriedades específicas.

- Processamento e Moldagem: O polietileno bruto é então processado e moldado em produtos finais, como embalagens, garrafas, tubos e filmes plásticos.

Levando em consideração a última etapa, a análise de balanço de massa poderia ser ilustrada pelo seguinte cenário:

1. Entrada de Matéria-Prima:

- Polietileno de Alta Densidade (HDPE): 1000 kg

- Aditivos: 50 kg

2. Processo de Moldagem por Injeção:

- Fusão e Mistura: O HDPE e os aditivos são aquecidos e misturados até formarem uma massa homogênea.

- Injeção: A massa fundida é injetada em moldes sob alta pressão.

- Resfriamento e Solidificação: O material é resfriado nos moldes até solidificar.

3. Saída de Produtos:

- Produtos Moldados: 950 kg

- Resíduos e Rebarbas: 100 kg

Para realizar a análise de balanço de massa, seguimos os seguintes passos:

- Definição do Sistema: Consideramos o sistema como o processo de moldagem por injeção, desde a entrada de matéria-prima até a saída dos produtos moldados e resíduos.

- Equações de Balanço de Massa:

- Balanço de Massa Total: Entrada Total=Saída Total

1000kg (HDPE) + 50kg (Aditivos) = 950kg (Produtos Moldados) + 100kg (Resíduos) = 1050 kg

- Balanço de Massa Total: Entrada Total=Saída Total

A análise mostra que a massa total de entrada é igual à massa total de saída, indicando que não houve perdas não planejadas no processo. Além disso, os resíduos e rebarbas representam uma perda de 100 kg, que pode ser reciclada ou reutilizada no processo para melhorar a eficiência.

Análise de Balanço de Massa no processo do plástico de polietileno

A análise de balanço de massa na produção de polietileno é uma atividade crítica e complexa, exigindo precisão e conhecimento técnico aprofundado devido às múltiplas variáveis envolvidas. O processo começa com o craqueamento a vapor de hidrocarbonetos para a obtenção de eteno, seguido pela polimerização que forma o polietileno. Essas etapas envolvem diversas reações químicas simultâneas, realizadas sob condições extremas de temperatura e pressão, o que demanda controle rigoroso e contínuo.

A utilização de catalisadores, essenciais para acelerar as reações, introduz outro fator de complexidade, pois sua eficiência pode variar com o tempo e as condições operacionais. Além disso, o processo inclui a reciclagem de gases não reagidos, que retornam ao reator, e etapas de purificação e separação do produto final, todas devendo ser consideradas no balanço. A gestão de resíduos e subprodutos, fundamental para a conformidade ambiental, e a variabilidade nas matérias-primas e condições operacionais também impactam diretamente a precisão da análise.

Para que o balanço de massa seja eficaz, é imprescindível dispor de dados confiáveis, coletados por sistemas de monitoramento automatizados. Esses dados alimentam modelos que permitem mensurar rendimentos, perdas e eficiência em cada etapa — desde transferências entre tanques até operações de filtração e separação. O processo precisa operar de forma estável para garantir resultados consistentes.

Além de otimizar o desempenho produtivo, uma análise precisa contribui para a obtenção de certificações e conformidade regulatória. Na mineração, por exemplo, a contabilidade de metais deve atender ao código AMIRA P754, exigindo auditabilidade e transparência. Assim, a digitalização industrial e a coleta automatizada de dados tornam-se aliadas estratégicas na execução de balanços de massa robustos, seguros e em tempo real.

Saiba mais sobre a ST-One.