No dia 22 de março comemora-se o Dia Mundial da Água, que possui como objetivo a conscientização sobre a sua importância para a manutenção dos ecossistemas. Além do estímulo à sua preservação, e como parte desse compromisso, as indústrias vêm cada vez mais se adaptando à essa necessidade em suas atividades.

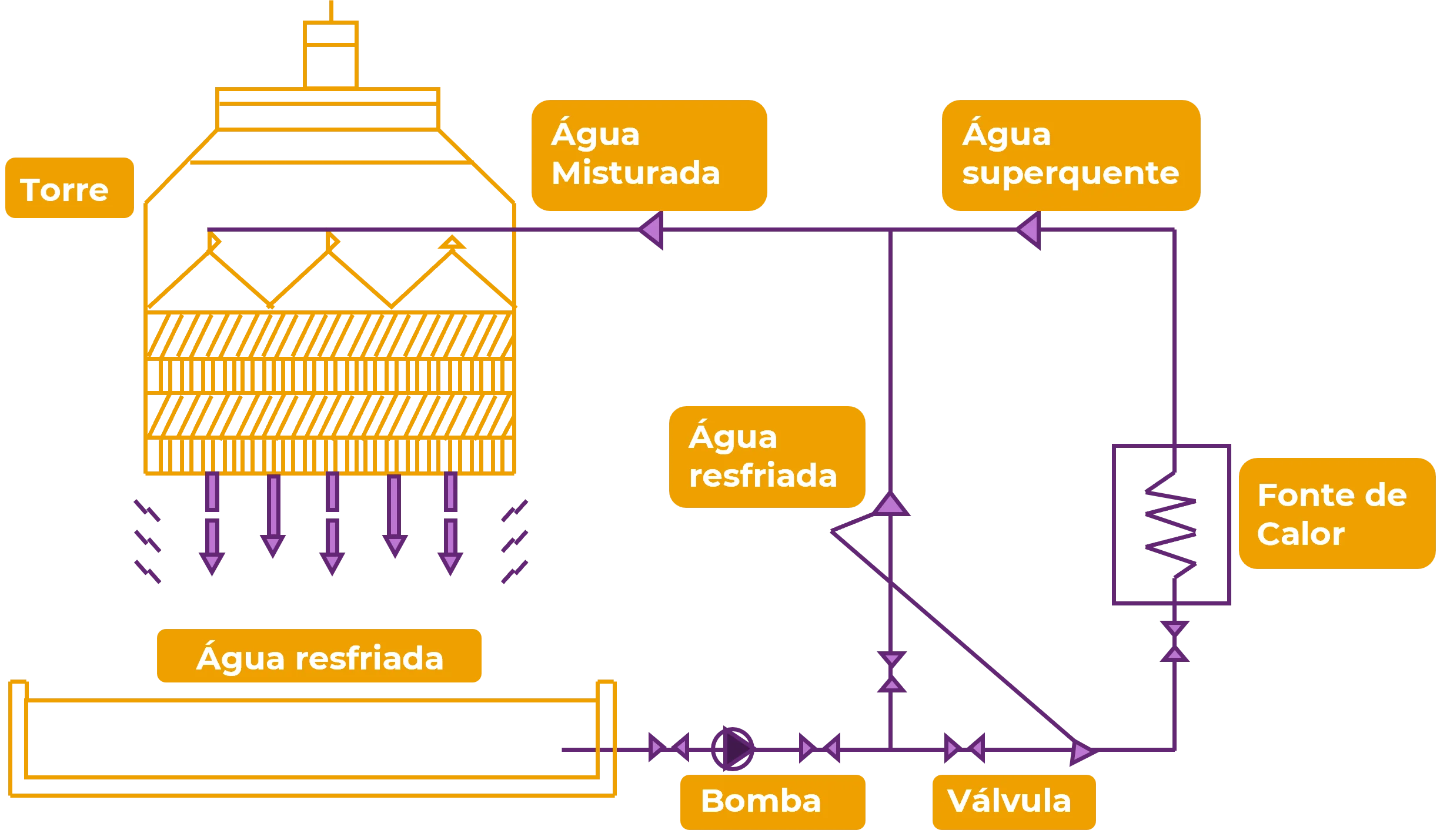

Dentro dessas indústrias, um processo amplamente utilizado é o resfriamento por água, onde o calor gerado em meios produtivos é dissipado através de transferência térmica. O resfriamento é essencial para evitar o superaquecimento de equipamentos, manter a eficiência operacional e garantir a segurança das operações.

Existem diversos métodos utilizados para esse fim e cada um possui vantagens e aplicabilidades específicas. No entanto, o que todos esses métodos possuem em comum são a eficiência energética, reutilização/circulação da água e controle térmico.

- As torres de resfriamento se destacam por sua eficiência energética e uso extensivo em indústrias químicas e de energia;

- Os chillers utilizam ciclos de compressão de vapor ou absorção para resfriar a água. São ideais para processos farmacêuticos e eletrônicos;

- Os trocadores de calor se mostram muito eficientes em processos que requerem separação de fluidos, como na indústria alimentícia.

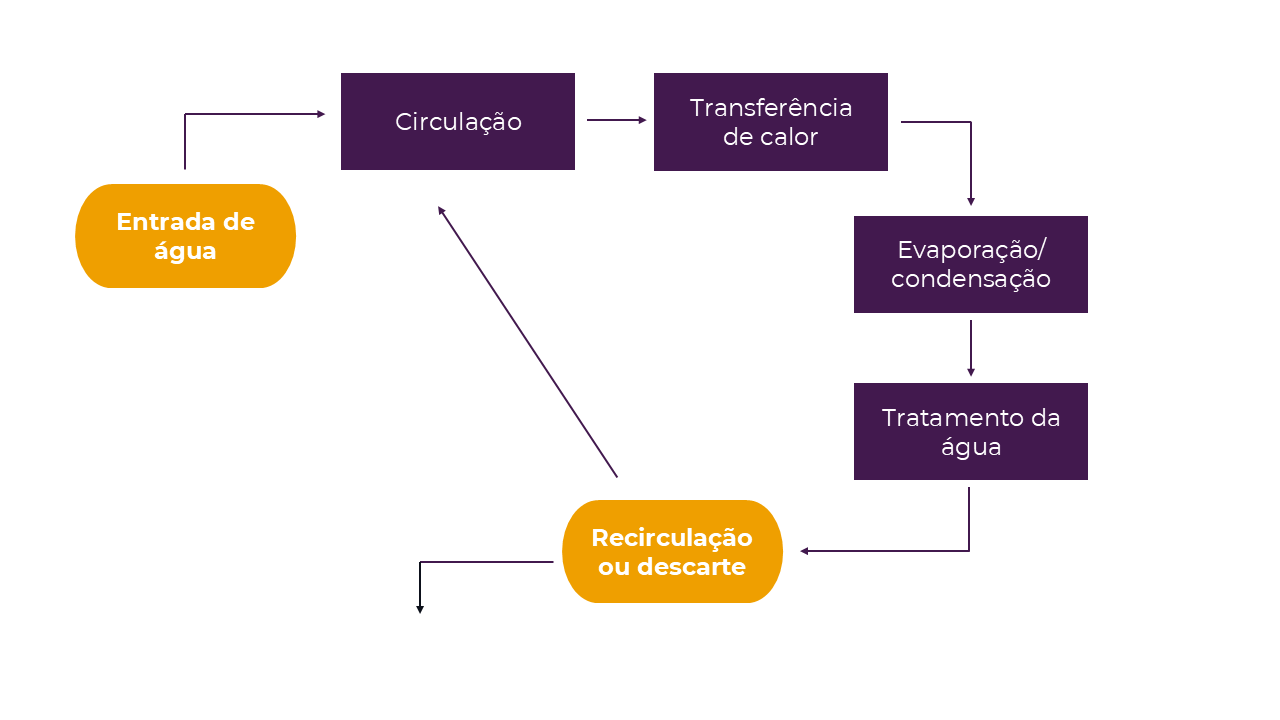

Como um panorama geral desses sistemas, os processos, em sua maioria, ocorrem da seguinte maneira:

- Entrada de água: a água é captada de uma fonte externa (rios, lagos ou poços) ou pode ser reutilizada de processos industriais;

- Circulação: a água é bombeada para os sistemas de resfriamento, como torres de resfriamento ou trocadores de calor;

- Transferência de calor: o calor dos equipamentos ou processos industriais é transferido para a água, resfriando os componentes ou fluidos envolvidos;

- Evaporação ou condensação: em torres de resfriamento parte da água evapora, removendo calor. Em sistemas fechados, o calor é dissipado sem perda significativa de água;

- Tratamento: a água é tratada para evitar corrosão, incrustação e crescimento microbiológico, garantindo eficiência e longevidade do sistema;

- Recirculação ou descarte: a água resfriada é recirculada para o sistema ou descartada de forma controlada.

Sustentabilidade em projetos de resfriamento industrial

Além dos possíveis processos já mencionados, há estudos que sugerem melhorias e inovações nesse âmbito. Uma pesquisa da Universidade de São Paulo (USP), em 2015, avaliou a viabilidade do uso de tratamento eletromagnético para a água de resfriamento em indústrias químicas. Essa técnica pode complementar ou substituir tratamentos químicos convencionais, reduzindo custos e impactos ambientais.

Além disso, a automatização desses sistemas também já pode ser uma realidade dentro das indústrias. É o que sugere o artigo apresentado a ConBRepro (Congresso Brasileiro de Engenharia de Produção) no ano de 2021. Os pesquisadores da UTFPR apresentaram a discussão sobre a aplicabilidade de softwares para otimizar os sistemas de resfriamento industrial. A automatização melhora a eficiência e a segurança dos trabalhadores, além de reduzir falhas operacionais.

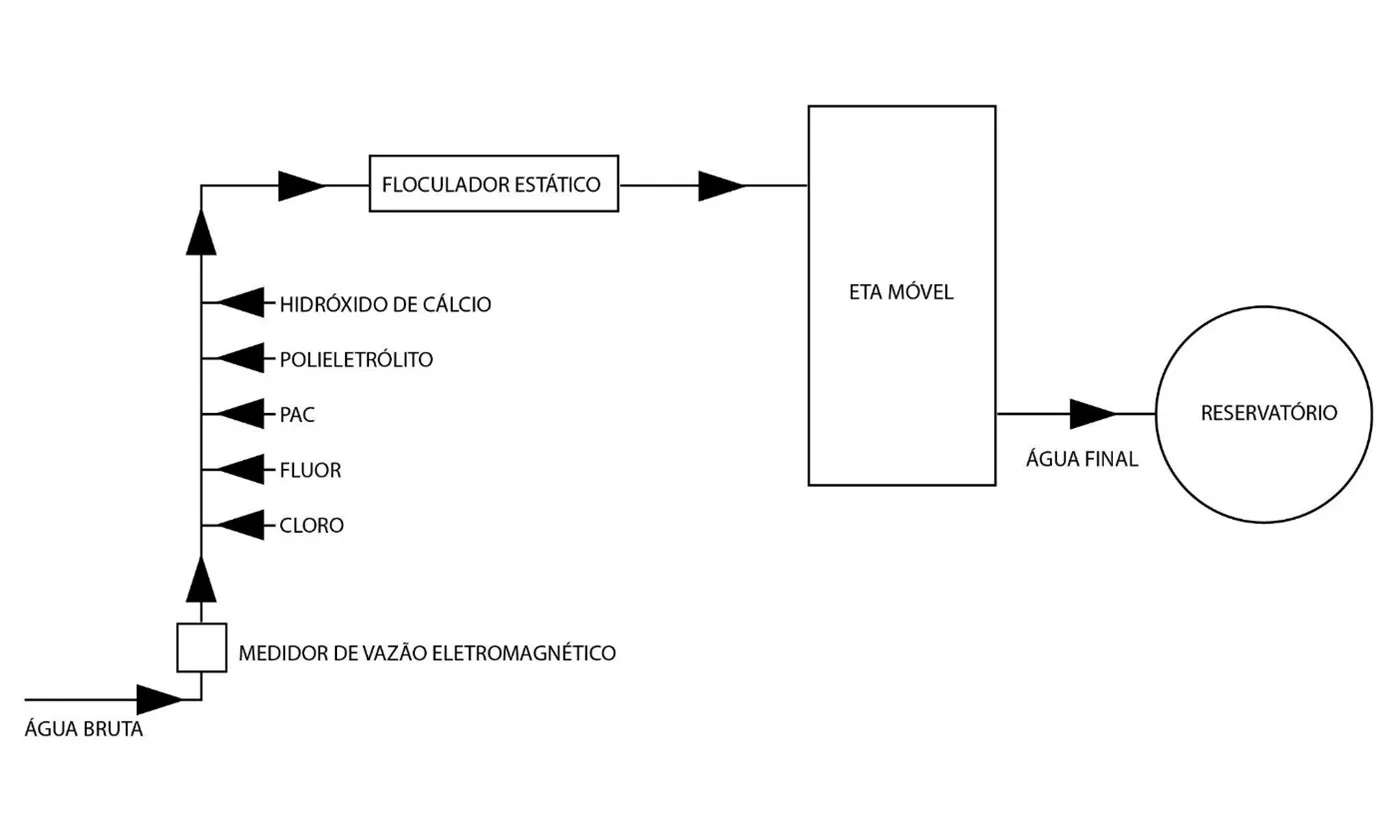

Outra contribuição para as indústrias é o projeto ETA Móvel, intitulado: “216m³/h em 18,5m²: a revolução da água em 30 dias”, executado pelo Tecnólogo em Gestão Ambiental, Paulo Alcino. Sua implementação permite o restabelecimento rápido da produção de água tratada, garantindo o abastecimento e minimizando os danos.

“(…) É a solução ideal para emergências, expansões urbanas e suporte temporário às ETAs convencionais. Sua implantação 93% mais rápida, operação simplificada, monitoramento preciso, mobilidade e custos reduzidos em 70%, além da sustentabilidade ambiental, fazem dela um marco de inovação”.

Sistemas de resfriamento em diferentes setores industriais

No documentário “O Código Bill Gates“, produzido no ano de 2019 e disponível na plataforma Netflix, Bill Gates destaca a importância de soluções sustentáveis em várias ocasiões. Um exemplo marcante é quando ele menciona sobre a crise de saneamento básico e a necessidade de inovação para resolver problemas globais, refletindo seu compromisso em utilizar a tecnologia e seus recursos para criar um impacto positivo no planeta.

Nesse sentido, dentro das indústrias, é necessário partir do mesmo princípio, especialmente em processos que envolvem altas temperaturas ou que demandam controle térmico rigoroso, podendo utilizar a água de forma consciente e sustentável para os processos de resfriamento. Alguns exemplos práticos são:

- Processos químicos: na produção de plásticos, colas ou produtos farmacêuticos, o resfriamento é necessário para manter a temperatura ideal e evitar reações indesejadas;

- Produção de alimentos: o resfriamento é usado para controlar a temperatura em processos como pasteurização, fermentação e armazenamento;

- Geração de energia: usinas térmicas e nucleares utilizam sistemas de resfriamento à água para condensar o vapor e melhorar a eficiência energética;

- Metalurgia: na fabricação de metais, o resfriamento é usado para solidificar materiais fundidos e controlar a temperatura em fornos e laminadores;

- Tratamento de resíduos: os sistemas de resfriamento ajudam a controlar a temperatura de gases e líquidos gerados em processos de tratamento de resíduos industriais.

Adotar práticas como o reuso da água em torres de resfriamento ou utilizar fontes renováveis, como água de poços, não só reduz custos como demonstra um compromisso com as metas ambientais, mas também a conformidade com ESG (Environmental, Social and Governance).

Aplicação dos processos de resfriamento por água

Conforme dados do Fundo das Nações Unidas para a Agricultura e Alimentos (FAO), a atividade industrial responde por aproximadamente 20% do uso global de água. No Brasil, de acordo com a Agência Nacional de Águas e Saneamento Básico (ANA), estima-se que o consumo do setor alcance mais de 215 m³/s em 2030, ressaltando a importância da preservação hídrica para garantir a sustentabilidade no futuro.

Nesse contexto, a eficiência no uso da água também inclui a continuidade no tratamento de efluentes para reuso. Isso permite que os resíduos tratados sejam destinados tanto a usos não potáveis, como irrigação, quanto a usos mais exigentes, como em torres de resfriamento e processos industriais. Essa abordagem reduz a demanda por água potável e assegura que os efluentes descartados em corpos hídricos estejam em conformidade com os padrões de qualidade estabelecidos.

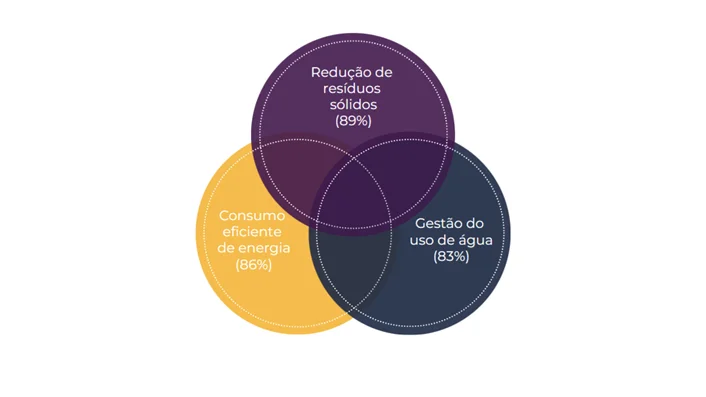

Além disso, mais iniciativas voltadas à promoção da sustentabilidade ambiental em seus processos produtivos foram tomadas. De acordo com uma pesquisa da Confederação Nacional da Indústria (CNI), em novembro de 2023, 89% das empresas industriais já tomaram medidas para minimizar a geração de resíduos sólidos. Além disso, 86% desenvolveram ações para tornar o consumo de energia mais eficiente e 83% implementaram estratégias para aprimorar a gestão e o uso da água.

Nos Estados Unidos, muitas indústrias estão adotando práticas de reuso de água e fontes renováveis para processos de resfriamento. Por exemplo, o setor elétrico utiliza cerca de 40% da água retirada no país para sistemas de resfriamento em usinas térmicas. Além disso, o reuso de água tratada está se tornando uma prática comum em indústrias como manufatura e produção de energia.

No México, o projeto Pacífico Mexinol utiliza tecnologias avançadas para reutilizar águas residuais municipais em um sistema de circuito fechado. Essa abordagem evita o uso de fontes de água doce, preservando recursos naturais e reduzindo o impacto ambiental. Dessa forma, é considerado uma das maiores aplicações de reutilização de água industrial no mundo, evitando o uso de mais de 8,5 milhões de m³ de água doce anual.

Saiba mais sobre a ST-One